From complete turnkey factories to individual machines, TIANTIE can provide customers with a wide range of standard equipment and custom recycling solution to help them achieve their business goals.

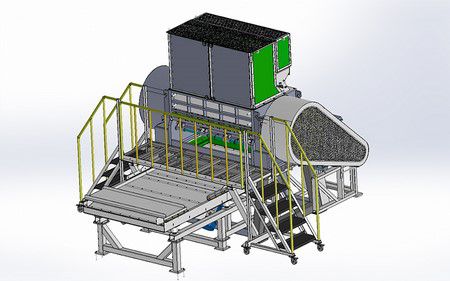

The four-shaft tyre shredder is a new product developed by our company. Compared to the tyre shredders available in the market, this tyre shredding machine is suitable for handling a wide range of tyre types and offers a stronger production capacity.