Rubber powder is the final product of an eco-friendly tyre recycling line. At this stage, rubber granules are ground into clean powders, completely removing almost all steel wires and fibers. Rubber powder has many secondary uses, including injection-molded products, coatings, roofing materials, and various asphalt applications.

Typically ranging in size from 400 to 74 microns (0.400 to 0.074 mm), micron-level rubber powder offers advantages for incorporation into new or existing polymers and finished products.

- Molded plastic applications

- Sealants and paint additives

- Modified asphalt thermoplastic applications

- Geomembranes

- Other extruded products and rubber compounds

- Stress-absorbing properties for asphalt applications

- Good performance and durability

- Capability to be incorporated into various polymers and products

- Reducing the environmental impact of tyre landfilling

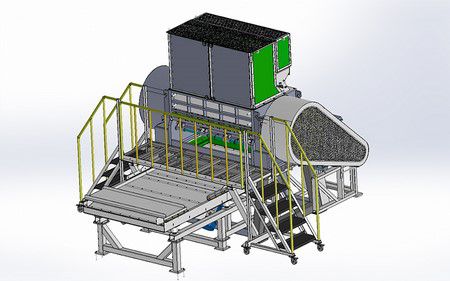

For manufacturers in need of rubber powder solutions, please feel free to contact us for a personalized tyre processing line! Our production line encompasses various processes, including tyre bead cutting, shredding, and metal and fiber separation, etc. The resulting rubber granules or powder can be extensively utilized in rubber product manufacturing, construction projects, road paving, and various other fields.