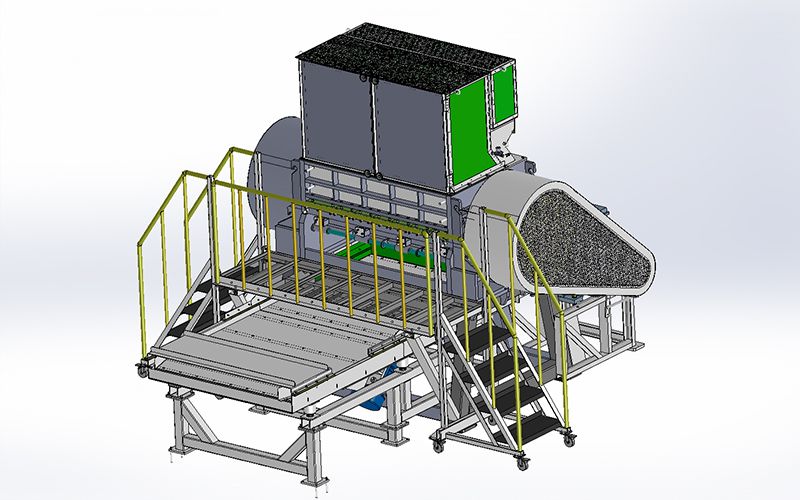

Tyre Chip Shredder

Size reduction machine used in tyre recycling line for reducing rubber chips into smaller particles

Tyre chip shredder is mainly composed of a feeding hopper, main shaft, and discharge hopper. It can crush rubber chips smaller than 50*50mm into smaller rubber particles measuring 18-20mm. The fixed blade has a service life of over 9000 tons, while the moving blade has a service life of over 4000 tons. The blades are detachable or repairable, ensuring a long lifespan and convenient maintenance. This size reduction machine has stable performance and a high load capacity, capable of shredding large and hard rubber chips, saving significant space and transportation costs.

Components

The tyre chip shredder consists of a feeding hopper, upper body, lower body, V-belt, main shaft, bearings, short blade, long blade, a screen insert, and a discharge hopper.